- Home Page

- Company Profile

-

Our Products

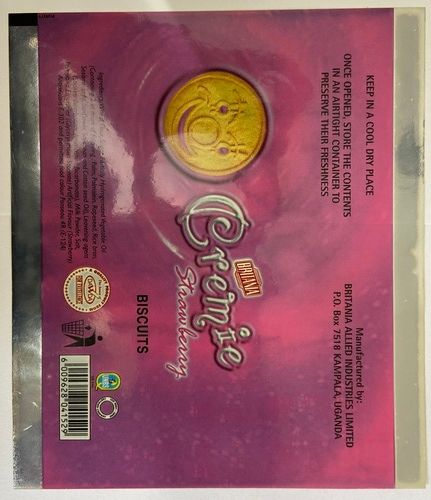

- Biscuit Wrapper

- Biscuit Flow Wrapper

- Cookies Packaging Materials

- Confectionery Packaging Material

- Snack Packaging Material

- Haldirams - Tata Tak Pouches

- Nilgiris Classic - Snacks Pouches

- Nilgiris Classic Vannila - Cake Slices Pouches

- Bauli Moonfils - Vanilla Pouches

- BAPS SHAYONA - MATHIYA Pouches

- Popcorn Snacks Pouches

- Haldirams Chip Pouches

- Haldirams Chips Pouches

- Chee-tos - Snacks Tomato Wheels Pouches

- Jim Boy Pouches

- Kailash Fryums Moon Chips Pouches

- Tangy Snacks Pouches

- Jadu Testy Namkeen Pouches

- Food Packaging Materials

- Fruit Drink Pouches

- Malai Paneer Pouches

- Bedekar Bhajni Pouches

- Hans Roasted Grams Pouches

- Hapus Milk Shake Pouches

- Savorit Semia Pouches

- Oral Rehydration Salts I.P Pouches

- PET Food Pouches

- Silver Pouches / Hotel Silver Pouches

- Pillsbury - Packaging Pouches

- Instant Drink Powder Pouches

- Bedekar - Chakli Masala Pouches

- Rasna Orange Pouches

- Customized Energizer Pouches

- Minerals And Powder Drinks Pouches

- Rasna Instant Drink Pineapple Pouches

- Flavoured Drink Pouches

- Bedekar Ready Pickle Mix Masala Pouches

- Industrial PET Food Pouches

- Winlyte Juice Pouches

- Coriander Powder Pouches

- Bedekar Goda Masala Pouches

- Customized PET Food Pouches

- Energy Drink Pouches

- Shrikant Masala Pouches

- Bedekar Saatvik Bhajni Pouches

- Palekar Butter Pouches

- Wonderfoods Bicarbonate Soda Pouches

- Butter Pouches

- Dairy Product Pouches

- Nenimeni Popcorn Pouches

- Real Crunch Pouches

- GRD Nutrition Development Pouches

- LUGAZI Ugandan Sugar Pouches

- Builder Kaju Yukt Meetha Mix Pouches

- Chandan Elaichi Supari Pouches

- Sea Cuisine - Seafood Sticks Pouches

- Wipro Low Calorie Sweetner Pouches

- Haldirams Salted Peanuts Pouches

- Dietary Food Supplement Pouches

- Chings Mix Veg Soup Pouches

- Bicarbonate Soda Pouches

- Charlies Munch Pouches

- Packaging Pouches

- Beta SIlver Pouches

- Packaging Materials

- Biscuit Packaging Material

- Tea Packing / Pouches

- Automobile Spare Parts Packaging Pouches

- Cosmetic Packaging

- PET Food Packaging

- Pharmaceuticals Packaging

- Seed Packaging

- Snacks Packaging

- Soaps & Detergent Packaging

- Supari Packaging

- Tea Packaging

- Tooth Paste Packaging

- Frozen Foods Bags / Pouches

- Salt Packaging

- Animal Medicine

- Animal Food Pouches

- Oil Packaging

- Paper Laminates

- Contact Us

Biscuits Wrapper Pouches

MOQ : 1 Ton

Biscuits Wrapper Pouches Specification

- Material

- Laminated Plastic Film (BOPP, PET, or MET PET with LDPE)

- Processing

- Gravure Printing/Rotogravure, Multi-layer Lamination

- Size

- Customizable

- Width

- 50 mm to 300 mm (custom sizes available)

- Thickness

- 25 to 60 Micron

- Length

- Customized as per requirement

- Transparency

- Opaque/Semi Transparent

- Hardness

- Soft/Flexible

- Color

- Multicolor; High-Gloss Finish

- Customized

- Yes, design and sizes can be fully customized

- Advantage

- Excellent moisture resistance, keeps biscuits fresh, premium print quality

- Feature

- Heat Sealable, Tear Resistant, Food Safe, Leak Proof

- Roll Form Supply

- Available in roll and pouch forms

- Application

- Biscuit Packaging; suitable for horizontal FFS & flow wrap machines

- Odor Proof

- Ensures no flavor loss or contamination

- Sealing

- High-quality heat sealable for airtight packaging

- Shelf Life Enhancement

- Protects against humidity, air, and light

- Surface Finish

- Glossy / Matte (as per order)

- Printing Technology

- High Quality Rotogravure/Gravure Printing up to 8 Colors

- Usage Industries

- Bakery, Biscuit, and Confectionery Industry

- Food Grade Compliance

- Yes, complies with FDA/IS standards

- Eco Options

- Biodegradable and recyclable films available (on request)

Biscuits Wrapper Pouches Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 60000 Tons Per Month

- Delivery Time

- 10-15 Days

About Biscuits Wrapper Pouches

FAQs

What type of packaging material is commonly used for cookies?

A significant market of roll bundling is covered by adaptable overlays of composite designs. They have advantageous dampness obstruction and gas hindrance properties, heat sealability as well as printability qualities. The various variations of plastic movies and their purposes are classified in table 1.

What are the methods of packaging of biscuits?

Most makers will bundle bread rolls in firm close wraps since clients will more often than not partner these with firm items that are not broken, not at all like the floppy film packs. Bundling that utilizes polypropylene film as a solitary wrap won't feel really that firm with multi-handle wraps of paper or cellophane

What are packaging techniques?

- Various Sorts of Bundling Techniques: Made sense of

- Paperboard Boxes. Paperboard boxes are one of the most well-known sorts of bundling. ...

- Bottle and Containers. Containers and containers are another famous bundling strategy. ...

- Shrivel Wrap. ...

- Pivoted Compartments. ...

- Plastic Compartments. ...

- Clamshell Bundling. ...

- Foil-Fixed Sacks. ...

- Chipboard Bundling Boxes.

Advanced Printing for Superior Branding

Featuring high-quality rotogravure and gravure printing up to 8 colors, our biscuit wrapper pouches create striking, multicolor designs that elevate brand visibility. The premium print quality ensures that every detail of your packaging stands out, helping your products attract attention on crowded retail shelves while reinforcing brand identity.

Engineered for Product Protection and Freshness

Our wrappers are designed with laminated plastic films-BOPP, PET, or MET PET with LDPE-that provide an effective barrier against moisture, air, and light. This advanced construction maintains biscuit freshness, locks in flavor, and prevents contamination, extending shelf life and ensuring your customers enjoy the intended taste and crunch.

Versatile Applications and Tailored Options

We cater to diverse needs across the bakery and confectionery industries, offering wrappers compatible with horizontal form-fill-seal and flow wrap machines. With full customization on size, finish, and thickness, as well as eco-friendly material options, we provide packaging that adapts perfectly to your unique requirements and sustainability goals.

FAQ's of Biscuits Wrapper Pouches:

Q: How are the biscuit wrapper pouches printed for high-quality results?

A: Our biscuit wrapper pouches are printed using advanced rotogravure or gravure technology, accommodating up to 8 vivid colors. This method ensures sharp, premium-quality designs that remain consistent throughout large production runs, enhancing your product's shelf presence.Q: What sizes and thickness options are available for customization?

A: We offer fully customizable sizes ranging in width from 50 mm to 300 mm and thickness from 25 to 60 microns. Lengths and other dimensions can also be tailored according to your packaging requirements, ensuring a perfect fit for your products.Q: When should I choose glossy versus matte surface finishes?

A: The choice between glossy and matte finishes depends on your brand aesthetic. Glossy finishes deliver a bright, reflective look that can make colors more vibrant, while matte offers a muted, sophisticated appeal. Both finishes maintain the same protective and functional properties.Q: Where can these biscuit wrapper pouches be used?

A: These pouches are suitable for packaging biscuits, cookies, and other bakery items, and are widely adopted in the bakery, biscuit, and confectionery industries. They can be used with horizontal FFS and flow wrap machines for efficient, automated packaging.Q: What process is involved in producing these packaging pouches?

A: Production includes gravure or rotogravure printing followed by multi-layer lamination, resulting in a strong, moisture-resistant, and food-safe wrapper. The process ensures excellent sealing properties and long-lasting protection for the contents.Q: What are the benefits of using these pouches for biscuit packaging?

A: Our wrappers offer outstanding moisture resistance and airtight heat sealing, which helps keep biscuits fresh and flavorful while preventing odor transfer and contamination. The customizable design and premium print quality also enhance product appeal and differentiation in the marketplace.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Biscuit Wrapper Category

Coustomize Biscuits Wrapper Pouches

Price Range 1.80 - 2.25 INR / Kilograms

Minimum Order Quantity : 1 Ton

Hardness : Other, Soft/Flexible

Size : Customizable as per requirement

Advantage : Moisture Proof, Attractive Printing, Tear Resistant

Width : Up to 500 mm

Digital Printed Biscuit Wrapper Pouches

Price Range 1.80 - 2.25 INR / Kilograms

Minimum Order Quantity : 1 Ton

Hardness : Other, Soft & Flexible

Size : Customizable as per requirement

Advantage : High quality print, fast turnaround, small quantity runs possible

Width : 50 mm 300 mm

Cookies Pouches

Price Range 1.80 - 2.25 INR / Kilograms

Minimum Order Quantity : 1 Ton

Hardness : Other, Soft & Flexible

Size : Customizable

Advantage : Moisture Proof, Retain Aroma & Freshness

Width : 80 mm to 400 mm

Biscuit Wrapper Pouches

Price Range 1.80 - 2.25 INR / Kilograms

Minimum Order Quantity : 1 Ton

Hardness : Other, Soft/Flexible

Size : Customizable as per requirement

Advantage : Excellent seal strength, moisture barrier, retains product freshness

Width : Typically ranges from 50 mm to 300 mm

We are accepting minimum order quantity 1 Ton.

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese